Responsible Sourcing

Building Climate Resilient Supply Chains

Palm oil is one of the world's most widely used commodities, and its global demand is projected to grow with the world's rising population.

With this growing demand comes a genuine concern that palm oil production is driving deforestation, and as the leading producer of sustainable palm oil, we share this concern too. We believe that traceability is the next frontier in halting deforestation: tracking supply back to its source will make it possible to identify where problems exist. To ensure that accurate information is available, producers and traders of palm oil need to establish a chain of traceability that is able to map our palm oil from source to supply.

Our Responsible Agriculture and Human Rights Charters outline our firm commitments to No Deforestation, No Peat and No Exploitation (NDPE). We strive to ensure our operations adhere to standards that meet or exceed these commitments and focus on supporting other industry actors to do the same.

To meet these commitments, we must ensure that every actor in our supply chain is committed to the same standards. SD Guthrie expects all suppliers of fresh fruit bunches (FFB), crude palm oil (CPO), and its derivatives to abide by our Responsible Sourcing Guidelines (RSG). The RSG translates our NDPE commitments into business relationships. It enables us to engage with suppliers and obtain their commitment that all supplied products come from legally compliant, environmentally sustainable, and socially responsible sources.

Visit SD Guthrie International's Supply Change Management to see our global sourcing footprint, as well as progress to resolve grievances within our supply chain.

Our Initiatives

Traceability

Monitoring Deforestation

Crosscheck

Working With Suppliers

Supplier Risk Assessment

Smallholder Development

Traceability

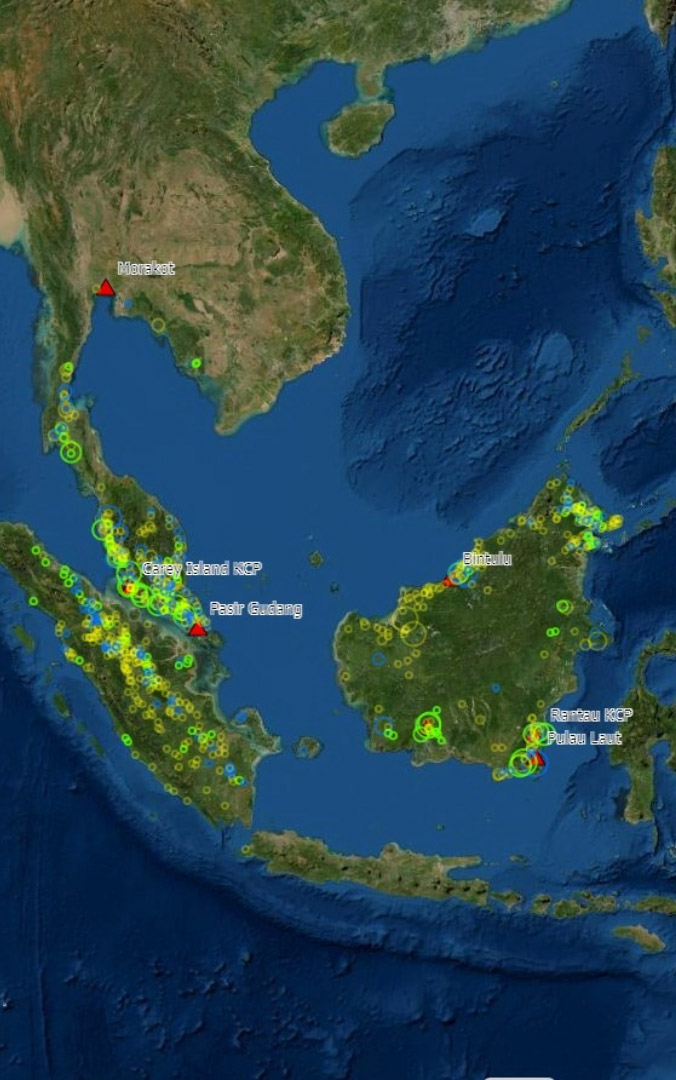

SD Guthrie as well as our downstream arm SD Guthrie International are committed to a traceable and sustainable supply chain. Our aim is to ensure 100% visibility of our supply chain and progress in implementing our No Deforestation, No Peat and No Exploitation (NDPE) commitments via Crosscheck. It is an open online traceability dashboard providing details of our global sourcing footprint, as well as our progress to resolve grievances within our supply chain.

Our focus to achieve full traceability of our supply chain is currently on Malaysia and Indonesia because our FFB from PNG and Solomon Islands has been fully traceable to plantation. We source 100% from our own RSPO-certified estates and smallholders in that region, all of whom have been subject to the company’s RSPO certification processes since 2012. In 2021, we achieved 100% traceability to plantation for SD Guthrie mills and 34.5% for third-party mills, resulting in overall traceability of 73.5% to plantation. Compared to 2019, this is an improvement of 25.7%, owing to our continuous focus on retrieving and mapping plantation data from our third-party suppliers.

We have set a target of achieving 100% overall traceability to mill and plantation. By 2023, we will engage a third-party expert to verify all traceability data, lending greater credibility to our reporting. We previously reported a target of full traceability to SD Guthrie-owned mills by 2022. However, we continue to face challenges with indirect smallholders we source from Malaysia. Whilst we have made some progress by mapping over 3,495 smallholders in recent years, there is still a long way to go. Nevertheless, we continue to work on traceability on all fronts and will report our progress against our traceability target.

We assess traceability to mills based on volumes supplied to each of our refineries and palm kernel crushers for the following categories:

- Crude Palm Oil (CPO);

- Palm Kernel (PK);

- Crude Palm Kernel Oil (CPKO); and

- Refined Palm Product.

A mill is deemed to be traceable if the information listed below is complete:

- Parent Company name

- Mill Name

- RSPO certification status

- Address

- Longitude and latitude coordinates

Crosscheck

While we were committed to establishing a fully traceable supply chain, we knew it is just as important to make it accessible for anyone. That is why we developed Crosscheck - an online open-source traceability tool that provides visibility on the origin of fruits and crude palm oil we process. Transparency makes it possible to identify where supply chains are associated with deforestation on the ground.

On Crosscheck, users can explore:

- Our supply chains from refineries to plantations and smallholders;

- Profiles of our and third-party supplier mills combined with Global Forest Watchs’ risk ratings and summary of grievances where applicable;and

- Forest, peat areas, and our conservation projects in high carbon value landscapes.

Monitoring Deforestation

SD Guthrie has consistently joined hands with like-minded partners to tackle deforestation. One of our most successful collaborations is the Radar Alerts for Detecting Deforestation (RADD), a publicly available radar-based forest monitoring system that was developed with the cooperation and funding from a coalition of ten major palm oil producers and buyers. Developed by Wageningen University and Satelligence, and facilitated by World Resources Institute, the RADD system augments existing publicly available monitoring tools that rely on optical-based satellite imagery, which can be delayed when clouds obstruct the view of forests. Through the use of radar waves, this system can penetrate cloud cover and gather forest change information without being affected by clouds or sunlight.

Battling deforestation is not a task for any single organisation. It calls for a collective action that creates a ripple effect throughout the agricultural industry, especially the palm oil sector. SD Guthrie has consistently joined hands with our colleagues to tackle deforestation. One of our most successful collaborations is the Radar Alerts for Detecting Deforestation (RADD), a publicly available radar-based forest monitoring system that was developed with the cooperation and funding from a coalition of ten major palm oil producers and buyers. This includes Bunge, Cargill, Golden Agri-Resources (GAR), Mondelēz International, Musim Mas, Nestlé, Pepsico, SD Guthrie, Unilever, and Wilmar. RADD complements our deforestation monitoring initiatives in partnership with AidEnvironment.

For more information click here.

Working With Suppliers

Our global operations involve a number of stakeholders including third-party suppliers. To achieve a fully transparent and traceable supply chain we need to extend responsible sourcing initiatives to our external stakeholders. By strictly adhering to our Responsible Sourcing Guidelines (RSG) when buying third-party crops, we inevitably introduce sustainable practices and standards to our suppliers.

The RSG enables us to engage with suppliers and secure their commitment to ensure their products come from legally compliant, environmentally sustainable, and socially responsible sources. It clearly outlines the expectations we have on our suppliers, which are expressed in SD Guthrie's Responsible Agriculture Charter (RAC), Human Rights Charter (HRC), and Code of Business Conduct (COBC). The RSG also complements SD Guthrie's Policy Statement on Working with Suppliers to Draw the Line on Deforestation.

Drawing The Line – Our Approach

Our ambition is to draw the line on deforestation and the practices that contribute to it across the industry. We have updated our approach to working with suppliers through our Draw the Line policy that clearly outlines the No Deforestation, No Peat, No Exploitation (NDPE) standards as well as our expectation that suppliers adhere to those same standards.

At SD Guthrie, we believe that we need to provide a path to re-engagement. In our view, suspension alone does not improve practice, and often has the unintended consequence of driving poor practice elsewhere into the industry's supply chain. Therefore, if a non-compliant supplier commits to stopping clearance immediately and putting in place a plan to meet our conditions, we are prepared to re-engage with them and support their progress to NDPE in hopes to attain our ultimate goal in expanding the sphere of oil palm companies operating to NDPE standards and drive deforestation out of palm oil production.

In the event a supplier violates NDPE standards, they are required to:

- stop work immediately on the affected land;

- develop a plan to remediate the damaged forest, including conducting High Carbon Stock Approach (HCSA)/HCV assessments, as necessary; and

- develop a programme to improve their ongoing operational practices to meet NDPE standards.

If the supplier concerned is unwilling to make these commitments, we will only then remove them from our supply chain. Once a supplier is no longer in our system, purchases will not resume until they meet the conditions above.

Supplier Risk Assessment

We regularly screen and evaluate our suppliers for news or reports on legal, community, labour, environment, and liability aspects. In addition to this, we use the Global Forest Watch Pro to analyse forest cover, peat areas, protected areas, and land clearings in our supplier's sourcing zone.

Find Out MoreGrievance Management

Our grievance management system has been established to address complaints from various stakeholders, including individuals, government organisations, and non-governmental organisations (NGOs) relating to non-compliances to our No Deforestation, No Peat, No Exploitation (NDPE) commitments. We verify all allegations received and updates on the investigations are published on our Supplier Grievance Register which. This register is updated every quarter.

We also make available grievance data on our Crosscheck platform to help stakeholders understand issues based on their location and links to other actors in the supply chain. We maintain regular communication with impacted stakeholders and grievance filers to address their concerns whilst investigations are in progress. We recognise that resolving complex grievances may require lengthy verification and mediation measures but are committed to addressing all grievances in a fully transparent and accountable manner.

We have publicly shared grievance updates since 2015.

Smallholder Development

Smallholders are important stakeholders in our supply chain. We understand that smallholders face numerous challenges in their production processes, including access to cost-efficient materials and technological advancements to improve yields, especially in view of extreme climate pressure. We recognise that without addressing the concerns of smallholders, we simply cannot claim a fully sustainable and responsible supply chain.

We are guided by our Responsible Sourcing Policy when sourcing for external fresh fruit bunches (FFB) from smallholders. The policy strictly adheres to the No Deforestation, No Peat, No Exploitation (NDPE) standards. However, if a smallholder does breach the NDPE, it is not our policy to suspend them. Working with smallholders needs a different approach that is guided by dedicated programmes to help build their capacity. We work actively in partnership with governments of countries we operate in to lift smallholders to a certifiable standard of sustainability, so they can continue to earn a living without causing harm to the environment.

We currently work with independent smallholders in Malaysia and scheme smallholders across the rest of our supply chain in Papua New Guinea and Indonesia. We take a localised approach to meet the needs of communities in each of the geographical landscapes we operate in.

In Malaysia, our goal is to include our smallholders into the sustainably certified circle. That is why, SD Guthrie has welcomed the Malaysian government's mandatory Malaysian Sustainable Palm Oil (MSPO) Certification Scheme. The MSPO is targeted at oil palm plantations, independent and organised smallholdings, and palm oil processing facilities.

Unfortunately, Malaysian smallholders face numerous challenges that impede certification. They are harvesting palms that produce less fruit and oil and live on small incomes, leaving them open to exploitation. Most of them are unable to pay for the improvements needed to carry out the certification process. They often do not even have the land deeds that are a basic requirement of the certification process or lack the license to trade Fresh Fruit Bunches (FFB).

Our supply chain in Indonesia comprises Kredit Koperasi Primer Anggota (KKPA) smallholders and Plasma Scheme smallholders. Through this scheme, the KKPA land holdings are managed by SD Guthrie while the smallholders are allocated share certificates for oil palm cultivation in their concessions. In exchange for the share certificates, the smallholders receive an income from the profits generated while the local communities enjoy additional work opportunities as well.

Plasma smallholders, on the other hand, are those who took part in the Plasma Transmigration Program (Perkebunan Inti Rakyat, also known as PIR-Trans), set up by the Indonesian government in 1987. Plasma schemes are managed by the community farmers who sell their Fresh Fruit Bunches (FFB) to SD Guthrie.

We received our first Roundtable on Sustainable Palm Oil (RSPO) smallholder certification for KKPA smallholders in Indonesia in 2014. The total operational area under the smallholder certification was 16,639 hectares with a total production capacity of 347,749 metric tonnes of fresh fruit bunches . As a result of this first smallholder certification, three mills achieved segregated status under the RSPO Supply Chain Certification System (SCCS).

In 2023, we continued to support over 21,000 smallholders, encompassing both scheme and independent smallholders, to ensure their adherence to our Responsible Sourcing Guidelines and ultimately, achieve RSPO certification. While the number of certified smallholders decreased in 2023 due to operational divestments, dedicated local teams continue to assist them in improving market access and livelihoods. We remain committed to increasing the number of certified smallholders within our supply chain and are actively supporting those currently undergoing the certification process.

Our most successful smallholder stories are in Papua New Guinea (PNG). All our smallholders in PNG have been certified to the Roundtable on Sustainable Palm Oil (RSPO) since 2013, and they received a significant sustainability premium. As SD Guthrie is able to sell their oil as segregated (sustainable palm oil from different certified sources that is separated from the ordinary palm oil), we calculate premiums for smallholders based on both the published RSPO premiums and our own premiums received on the sale of Certified Sustainable Palm Oil (CSPO) converted to FFB equivalents. The premium is paid to each smallholder based on their production with no administrative charges or other deductions. We cover all smallholder certification costs, and these are not charged back to the growers. In 2023, smallholders earned collective premiums of 8,707,846 PGK (or USD 2.19 million). The premium paid to each smallholder is based on their production with no administrative charges or other deductions

To understand how we can bring additional smallholders into our supply chain in Papua New Guinea (PNG) and the Solomon Islands (SI), we carried out assessments for smallholders interested in developing their land and guided their implementation of the RSPO's New Planting Procedure. We also actively share best practices to help farmers obtain the skills and knowledge they need to manage their oil palm blocks. SD Guthrie uses visual aids and provides simplified learning tools to increase smallholders' knowledge on topics including FFB quality, planting cover crops, applying fertilisers, as well as the costing and pricing of their products. We conduct these activities during field days, block demos, and through our financial literacy training sessions.

Supporting smallholders through financial literacy

Aside from certification, our NBPOL sites carry out programmes with local communities on land use planning, gender empowerment, and sharing best practices to help farmers obtain the skills and knowledge they need to manage their oil palm blocks and improve their livelihoods. One such programme provides financial literacy support to smallholders and landowner groups through a train-the-trainer model that covers topics such as budgeting, financial planning, sound financial practices, and banking. We also facilitate the opening of personal bank accounts for interested members.

Improving the socioeconomic status of smallholders

Low productivity caused by social and economic factors is the main challenge facing oil palm smallholders. NBPOL is collaborating with the PNG Oil Palm Research Association’s (PNGOPRA) Smallholder and Socioeconomic Research Division to conduct extensive research and provide technical advisory services to smallholders. This includes conducting research on fertiliser programmes that best maximise yields for smallholders, understanding the effectiveness of smallholder training on best management practices provided by SD Guthrie, and understanding smallholders’ income and expenditure patterns. Through this research, we aim to better understand these social and economic factors and improve our programmes to address smallholder productivity and strengthen the country’s economic, environmental, and social well-being.

Approximately 95% of the overall palm oil production in Thailand comes from smallholders. Currently, there are about 285,000 farmers across Thailand with an average plantation land of approximately 2.5 hectares. Most palm oil mills in Thailand are independently owned and lack the resources necessary to implement sustainability and certification programmes. As we work further down the supply chain, it becomes increasingly challenging to reach smallholders and work with them. Due to the significant contribution of smallholders in Thailand, we understand that strong collaborations with other stakeholders in the supply chain is integral to move everyone on the sustainability journey.

Our refinery in Thailand, Morakot Industries, has established a smallholder programme in collaboration with local mill partners, to help smallholders achieve certification, and to secure a steady and reliable supply of Certified Sustainable Palm Oil (CSPO) into its supply chain.

The smallholder certification programme was established in 2018 and identified 6,000 smallholders with a production capacity of over 300,000 MT of Fresh Fruit Bunches (FFB) per year. These smallholders are divided into 10 groups based on their location – that is, whether they are located within 50 km radius of an identified mill. We then run a series of engagement sessions to raise smallholder awareness about certification processes and to better understand the needs and challenges faced by the smallholders in Thailand.

We encourage smallholders to complete certification processes by paying out premiums as an incentive for the production of certified sustainable palm oil. As of 2019, we now have a supply of fully segregated CSPO from 592 smallholders. During this period, we also signed a Memorandum of Understanding with Narathiwat Cooperative and Panom Cooperative, two out of 10 smallholder collectives. Panom Cooperative has successfully received its RSPO certification and currently supplies to S.P.O. Agro-Industries Co. Ltd. Mill.

Our aim is to enable 700 smallholders in our Thai supply base to supply certified Identity Preserved palm oil by the end of 2020.

In 2019, we committed to expanding our current supply of CSPO Mass Balance to Identity Preserved (IP) / Segregated (SG). This means we ensure sustainable palm oil from a single identifiable certified source and different certified sources are kept separately from other palm oil throughout the supply chain.

All smallholders must adhere to the same Responsible Sourcing Guidelines criteria we impose on all FFB suppliers. However, we recognise that many smallholders may have difficulty meeting these criteria despite making commitments because they lack capacity, know-how, and access to financial resources. Given the significant volumes produced by smallholders, supporting their transition to sustainable practices is crucial to transforming the industry and ensuring that SD Guthrie achieves our NDPE ambitions.

Our goal is to ensure 100% of all supply sourced is NDPE-compliant by 2025, including smallholder supply.

Therefore, we have developed programmes across our upstream operations to support scheme and independent smallholder certification as a gateway to sustainable production. These programmes build capacity and train smallholders to improve production efficiency and secure higher yields. They also reduce barriers to market access and provide support to meet certification requirements.

Our community programmes also focus on proper land use planning, management committee responsibilities and community needs assessments. Training programmes are designed to equip smallholders to plan their finances effectively, and we provide interest-free credit to help towards quality farm inputs like tools and fertilisers.

Climate change is a key component of smallholder programmes:

A major component of our programmes is helping farmers understand how climate change can impact their livelihoods and adopting climate-smart agriculture approaches. Our programme modules include responsible land use and conservation planning, adopting good agricultural practices on fertiliser application and moisture retention, and maintaining riparian buffer zones as part of flood mitigation. Smallholders in our supply chain can also potentially access planting material that is more climate-resilient. Transitioning smallholders to climate-smart agricultural practices is critical to SD Guthrie’s climate strategies and intricately linked to meeting our No Deforestation and No Peat requirements.

In 2022, SD Guthrie embarked on a 3-year Smallholders Inclusion Project with Solidaridad Network and Colgate-Palmolive. The project aimed to increase the adoption of Good Agricultural Practices (GAP) to improve farmers’ resilience against the challenges of climate change as well as increase demand for transparency and traceability, and ultimately, improve their livelihoods and sustainability standards. The project also focusses on responsible fertiliser application and chemical use to minimise land use change and reduce greenhouse gases (GHG) emissions. The Smallholders Inclusion Project targets smallholder palm oil suppliers in Perak, the state with the second-largest number of smallholders in Malaysia, accounting for over 37,000 farmers, according to the Malaysian Palm Oil Board (MPOB). This made Perak an ideal location for the implementation of the project to have a substantial impact.

The GAP training covers essential practices such as water use, fertiliser application, pest control, and waste management. It also equips farmers with the knowledge to comply with regulations on worker rights, safe work conditions, and fair treatment. As of February 2024, the project has trained more than 700 oil palm smallholders. For more information, click here.

As of December 2021, 50% of the smallholders that supply to us are RSPO certified through their participation in our certification support programmes. In 2021, they collectively sold over 961,000 tonnes of certified FFB to SD Guthrie mills

Whilst smallholders in Indonesia and Papua New Guinea (PNG) and Solomon Islands focus exclusively on obtaining RSPO certification, smallholders in Malaysia aim to comply with their country's mandatory national certification standard first by achieving Malaysian Sustainable Palm Oil (MSPO) certification. In Malaysia, 9% of smallholders are MSPO certified, independently or through programmes supported by SD Guthrie. We also know that less than 1% of the independent smallholders we source from in Malaysia are RSPO-certified.